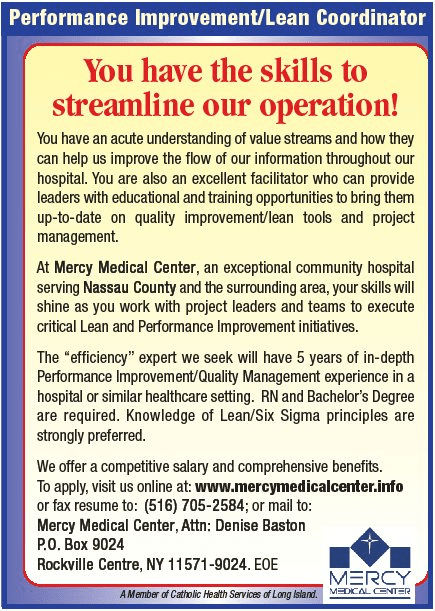

This blog post contains a real job posting, found online. Let's make this a reader participation challenge. I see maybe three things “wrong” or at least questionable about this posting. What say you? I'll let the readers chime in before adding my thoughts on the three things that make me go “hmmmmm.” Click “comments” to participate and I'll interact with you on this.

What are your reactions?

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

First thing I notice is the request to improve the flow of information in the hospital. This shows a lack of system thinking and jumping to conclusions. It’s not a given that improving flow of information will add more value for the customer.

Ah, that’s maybe a fourth one them. Is the job posting jumping to solutions rather than wanting the Lean person to help understand the problem and to help grasp the situation. Good point.

The “Effeciency” expert????? So this person can wave a magic wand and make things perfect, right. If I was able to do this, I WOULD NOT be working at a medical center!

That’s one of the three things that jumped out at me… why is “efficiency” in quotes while the word quality is not? Do they want pseudo efficiency? Either way, I don’t like using the term “efficiency expert” as it’s a dated term and downplays the quality component of Lean/TPS. Lean is not about the lone expert making improvements, it’s about coaching everybody to improve.

First thing I noticed is the headline- the assumption that the job is centered around “streamlining” the operation.

Good point, I’d rather see a term that’s less loaded, like “improve.” The word “streamline” seems to imply efficiency only or, worse, it implies cost cutting and layoffs.

The biggest resistance we see to Lean is the idea that Lean= Layoffs. So any publicly posted job with the word “streamline” will definitely generate resistance to Lean.

Yep I agree with these thoughts. Streamline is often used very loosely to mean improve (at all costs) or cutting flak, which some L.A.M.Ers have incorporated into common lean lingo.

It is a word borrowed from fluid dynamics where it has a very precise and technical meaning. But now, it’s another cold buzzword in business.

1) “You have an acute understanding of value streams”

As a Performance Improvement/Lean Coordinator do you have expert knowledge of their value stream? We may be able to observe the gemba and ask several questions in regards to people, process and purpose but in my experience the true experts on hospital value streams and their solutions are the employees that actually create and deliver value to the patient.

In addition to the employees what about the patients? I can guarantee you they are experts on the entire process not just processes within functional silos where employees work. Gaining insight from patients (our customer) helps create smooth horizontal flow from start to finish (in terms of the patient) not just in one department (the employees).

2) “You are also an excellent facilitator who can provide leaders with education and training opportunities…”

Again, what about the people that actually delivers the value added services? Shouldn’t we be training these people on lean in addition to leaders?

Leaders should be facilitators of engaging staff in second order problem solving. They need to ensure an operating environment and culture that can accomplish this (standard work, metric board management, visual controls, daily walk troughs, etc.)

Isaac – yes, the posting makes their Lean approach seem more inward focused than patient focused. And I agree that a Lean facilitator/coach should be working with people at all levels, not just leaders. But at least the posting references training leaders as opposed to just focusing on those who do the work (as if the leaders have nothing to learn).

Forgive me if I’m a little ignorant as I am not in the healthcare world, but is it typical to require a Process Improvement Leader to be an RN? I understand that having experience in that field is a positive and should be preferred, but you really restrict your self by making RN a requirement. I’ve worked in a couple of different environments (manufacturing, IT, and transactional/support) and it was never a requirement that I had a position or certification in that industry to work there.

I see it similar to requiring an accountant to be an RN. Sure there are some things that you need to know about the industry, but the basic principles of accounting (and Lean) are applicable.

Joey – that was the first thing to jump out at me, that the posting REQUIRES an RN degree, but lean knowledge is “strongly preferred.”

I think that’s totally backward.

To me, an internal Lean group should have a mix of clinical and non-clinical people. RNs can do a great job in a role like that, but so could an MHA graduate, an IT person, or an engineer.

I think this job posting illustrates the bias expressed by some that says “this Lean stuff is simple” and “we can just send you to a training course to be a Lean expert.” I see a lot of postings that require a clinical background, which shows some of the bias that you see in healthcare sometimes.

I see similar job descriptions asking for RN experience to be the Lean facilitator all the time too!

There’s still one more of my original 3 “hmmmms” that hasn’t been mentioned.

So far we have:

1) RN required, Lean experience “strongly preferred”

2) “efficiency” is put in quotes

3) ?????

[EDIT — LEWIS IDENTIFIED #3, BELOW]

Hi Mark,

One more that jumps out for me is “to execute Lean and Performance Improvement initiatives” which suggests they are mutually exclusive, but would hopefully be inclusive.

Yes, you could perhaps have a (limited) 5S initiative which, provides little “performance improvement”, but why would you..?

Perhaps another one is the inference there is only one person working on Lean/Improvements (though with with the help of “project leaders” etc)

Graham

Hi Mark,

Does this hospital have any paients or does it only for process information. There is NO mention of patients/customers in the advert which would concern me if I were looking to help embed Lean within the organisation.

In addition the facilitation refers to leaders, no mention of supporting & facilitating the empowerment of hospital staff to make improvements & enhance the patient experience.

Finally the advert suggests to me that the current hospital leadership (who presumably approved the ad) still have a lot of lean learning to do themselves, particularly relating to the culture & behaviours they need to instill to create a sustainable LEAN JOURNEY.

Jim

In my opinion, this ad implies that the organization is putting to much emphasis on the Lean Coordinator and not enough of the shared responsibility. For example, “You have the skills to streamline” and you understand “how they (value streams) can help us” makes it sound as if the organization isn’t sure what it is looking for but wants help. This is similar to hiring an individual hiring a psychatrist and stating the reason is “you have the skills to fix me.” It implies too much responsibilty to the shrink and not enough of the individual.

I would rather see the job ad read as “you have the ability to learn our systems, understand our issues, and help us eliminate waste using lean principles.”

“sound as if the organization isn’t sure what it is looking for but wants help.” You may be on to something here. Maybe they just made the ad by cutting and pasting Lean buzzwords hoping someone will answer!

If they did cut and paste, it could be a warning that “practices respect for people” wasn’t included.

The one word that caught my attention is “you”. The whole ad speaks about “you” doing all these projects, but never mentions joining a team of people with the same goals. It could be a situation where this hospital wants to start implementing lean methods, but I would expect this to be clearly mentioned.

Sonja – yes, discussions about Lean improvement should really include the word “we” more than the words “I” or “you” or “me.”

Seems to me these folks simply don’t know what they’re looking for because they don’t have clarity about what they hope to accomplish. Without that basic understanding it’s quite likely that even the best people applying won’t look all that different from the least qualified.

So Mercy will wind up hiring the least-expensive Kaizen Kowboy (an RN with lots of great Lean buzzwords on her resume) available in their local in the market, and pat themselves on the back for getting the bargain they did. And they’ll get exactly the level of experience, expertise and value for which they’ve paid.

Then, about 18-24 months, or sooner, when nothing much has actually happened (what Lean transformation?), they’ll conclude that Lean just doesn’t work. I suspect they’ll move on to Six Sigma…

Another sad case of the blind leading the blind into a future state of L.A.M.E.

For contrast, readers might want to check out the excellent position description recently posted by ZipCar in Boston. It’s over at http://www.linkedin.com/jobs?viewJob=&jobId=1790870

Adam Zak

Hmm, maybe the #3 on your list is the focus on “tools and project management”? While these are certainly important aspects, a sole focus on tools and projects is an absolute failure mode.

Good for them for wanting to improve and taking a step. Hopefully they don’t get exactly what they are asking for and that this too is part of their learning.

Lewis – yes, that was my #3 head scratcher. It’s a short job posting, but I hope the realize that tools are at best a piece of the puzzle, that they also need to focus on the management system and culture. No single lone wolf “lean person” can make an organization lean.

Adam hits the nail on the head with the status of Lean in the majority of Health Care Facilities. There is little desire to change the status quo in most Health Care facilities.

Thanks to everybody for the input and insights. I know I got more out of this by drawing out comments from my readers than if I had just posted my own rant (although I will reserve the right to post rants in the future… tomorrow is a bit of a rant).

So part of my reflection about this blog post includes wondering about the balance between saying “well, at least this hospital is trying and they might figure Lean out eventually” versus thinking “holy crap, this job posting has a lot of problems, we should say something.”

I also debated about posting something publicly versus just reaching out individually and privately… I hope I served a greater educational good by posting this publicly.

Recently went for a job like this – thankfully backed out.

Not just the lone wolf problem, but the ‘solution’ focus. This organization wanted someone to implement a technical efficiency solution they had already developed, and just wanted some process mapping to make sure the business process fitted their solution. Cue Lean.

No sense that the senior management, or the actual project team themselves wanted to think in a Lean way.

How would it have worked if I had seen an early opportunity for 5S in their workplace – “No, no, that’s not why we hired you”. Or if ‘them’ ie the front line staff and processes weren’t the biggest problem, but the head office management??? And I’ve seen that too often before.

Go out and ‘do’ ‘it’ to ‘them’ with no knowledge of what ‘it’ is, nor identification from management with ‘them’ to whom ‘it’ will be ‘done’.

Sorry I am a little late to this discussion. I agree with Adam on what a real lean job description might look like from the zipcar posting.

The one thing that stands out to me and bothers me is that lean(or even six sigma) knowledge is preferred. As in, it’s like a nice to have not a need to have. That is ironic.

Wow! My wife works at this hospital and works in the OR. She has been there for over 10 years. She told me that they were introducing lean to the OR that a man came in and gave a speech about it. I have a black belt in six sigma and also use lean manufacturing in my line of work. When she told me that I could not stop laughing. This is not going to work nor is it gauged toward paintents. This is a last ditch effort to try to correct a very miss managed OR. If management does not embrace or try to implement the change it will never work. The workers control the management, the management does not control the workers. Good luck.

John – did you laugh about it because their Lean effort seems misguided because it is not focused on patient needs? Because management doesn’t really embrace Lean (meaning that they also have to change their ways?).

Do you agree that Lean can work in healthcare (that there’s a huge need for it), if done right?

Good luck. Not just the lone wolf problem, but the ‘solution’ focus. For example, “You have the skills to streamline” and you understand “how they (value streams) can help us” makes it sound as if the organization isn’t sure what it is looking for but wants help. Because management doesn’t really embrace Lean (meaning that they also have to change their ways?).

RN required, 5 years experience in process improvement then mention lean/six sigma preferred ( pick one) , someone explain to me what an “acute” understanding is?

I have no idea… I guess it’s the dictionary definition that means “highly developed” as opposed to a sudden, sharp pain as “acute” might be used in a medical sense.

I still see silly job postings from hospitals all the time. I have been meaning to blog about that again.