Back in July, e-Patient Dave deBronkart noticed an article in the Health Leaders publication called “Taking On the Cost Drivers.” It inspired him to reach out to me and Alice Lee, from Boston's Beth Israel Deaconess Medical Center to write a response.

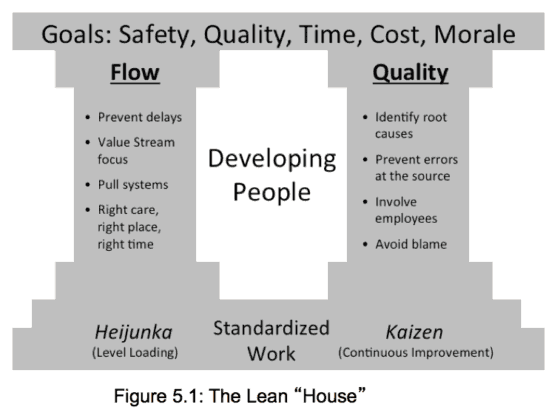

As we all read the article, it jumped out at us that Lean was portrayed as just a cost reduction strategy. Toyota's famous “house of TPS,” of course has a dual focus on flow (“just in time”) and quality (“jidoka”). Yet, people so often ignore the quality component. So, we wrote a joint letter to the editor.

Here is a version of the house from my book Lean Hospitals:

One portion of the article said this:

Lean is a strategy for cutting costs and boosting productivity, with an emphasis on eliminating waste and improving processes while providing more value to customers. Similarly, Six Sigma looks at reducing variations in processes, products, and services to reduce waste. The American Society for Quality conducted a study of 77 hospitals and found that 53% have some type of Lean initiative and 42% are using portions of Six Sigma.

I've challenged the statistical validity of that ASQ survey before. Argh, it's frustrating to see how a badly done non-scientific survey can get quoted as fact.

At least Health Leaders mentioned the idea of “more value,” I'll have to give them that much credit. Their distinction between Lean and Six Sigma might not have been that helpful to the uninitiated. But, it's better than the cringe-worthy statement that some make that says “Lean is about efficiency and Six Sigma is for quality.” Again, Lean is BOTH quality and flow. They go hand in hand.

The shortened letter appeared on the Health Leaders website.

To the Editors of HealthLeaders:

We want to voice a concern about one item in Karen Minich-Pourshadi's comprehensive June article, “Taking On the Cost Drivers.”

We think it misses the point by portraying lean as only a tool to right-size patient-staff ratios. Ultimately, lean can have that effect, but organizations do so by moving the focus off the ratios and spreadsheets and onto the floor, where the goals are quality and efficient flow of value — while meeting people's needs (customers and employees). Things that deliver value are identified and supported, and everything else is weeded out. More care typically can be provided with better quality – but not by seeking to right-size any single variable.

Example: at Beth Israel Deaconess we (Lee) applied Lean thinking to our orthopaedics clinic. We improved efficiency in many ways – for instance a 70% reduction in wasted time for patients and staff, which translated into better flow throughout the clinic. As a marvelous additional benefit: we now see an additional 100+ patients per week in the same space, with the same staff. This did not result from trying to right-size staff or cut costs – it came from examining, with rigor and a disciplined approach, how we go about everything we do. And there's no way the same bottom-line improvement could have been achieved with traditional cost-cutting. Similar success has been demonstrated in settings including ThedaCare, Seattle Children's Hospital, and other members of the Healthcare Value Leaders Network.

Yes, it is important to balance staffing with workloads and patient demand. But, even when headcount reduction is called for, leading lean hospitals have a policy of “no layoffs due to lean,” redeploying employees or relying on natural attrition. In some cases, especially where workloads had increased without staffing increases, the right data-driven approach might be to increase staffing, even after reducing waste. This might be necessary to make sure work can be done at the right quality levels, which in turn leads to lower costs.

Alice Lee, Vice President, Business Transformation, Beth Israel Deaconess Medical Center

Mark Graban, author, Lean Hospitals: Improving Quality, Patient Safety, and Employee Satisfaction

“e-Patient Dave” deBronkart, ePatientDave.com; Co-chair, Society for Participatory Medicine, and patient participant in BIDMC's lean workshop

And, as I wrote about last week – “right-sizing” can be done in a way that doesn't destroy morale in the organization… using attrition and redeployment instead of numbers-driven layoffs.

What's your take on their article and our letter?

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Mark,

All I can say to you, and Alice Lee, is — Bravo! In this space, I am preaching to the converted, but Lean is not about cutting costs – it is about maximizing value. Eventually, I hope that message gets through, but it will take responses like yours to sound the horn. The view expressed in the article seems to stem from the oh-so-difficult to dispel notion that Lean is a set of tools to be picked up and used, and not a philosophy and culture.

I am looking forward to hearing from Alice Lee personally at the Shingo Prize conference next month. Until then, carry on!

[…] Beth Isreal Deaconess Medical Center (BIDMC) gave an inspiring presentation on her experiences with cultivating a Lean Healthcare culture at a 10,000+ person hospital in Boston, MA. Her tale was a fascinating one, in that she […]