Due out in June is a book that I think will be an important one for the Lean Healthcare movement. That book is about the Lean journey of the Wisconsin health system ThedaCare. It's called On the Mend: Transforming Healthcare to Save Lives and Transform the Industry, published by the Lean Enterprise Institute (conflict of interest alert – they are were my employer).

ThedaCare is widely considered one of the leaders in the application of Lean in healthcare – delivering measurable results for improved quality (patient care and outcomes), reduced cost, reduced waiting times, and improved staff engagement. The book is written by ThedaCare's former CEO John Toussaint, MD, and their chief learning officer, Roger Gerard, Ph.D.

I've read the book many times (in its various forms and stages of editing) and I recommend it highly. I think it will definitely speak to healthcare executives about why we need Lean in healthcare and what their role needs to be in engaging employees and physicians.

As much as I like the book, I'll give this caveat that might be controversial — don't copy ThedaCare!

In my plea to not copy ThedaCare, I mean no disrespect to the work they've done. Far from it. What I mean is a cautionary statement to other hospitals that there “is no instant pudding,” as Dr. W. Edwards Deming once said. Too many organizations want a simple roadmap – they want to copy. Tell me what some other hospital did and we'll do it too. They want to implement Lean without having to think – it's not possible, well not if you want to be truly effective or have any chance of sustaining and continuously improving with Lean.

What's great about ThedaCare's story is that they learned from others and they didn't copy directly. They learned from Wisconsin manufacturers. They learned from general Lean books like “Lean Thinking.” When they used Lean principles to create their innovative “Collaborative Care” model (as shown here on Fox News), they didn't “benchmark” and copy another hospital. To quote Frank Sinatra, they did it “their way” – they innovated and used PDCA to refine their process designs. When ThedaCare reduced their “door to balloon” time from 90 minutes to 37 minutes, they didn't blindly copy another hospital.

Sami Bahri, DDS, the “world's first Lean dentist” had nobody to copy. So he read Ohno and Womack and Deming and Senge… and he taught his staff principles and they thought and experimented. He had no other “Lean Dentist” to copy. And I think that's a big reason why he's been successful. He shared his story in the book Follow the Learner: The Role of a Leader in Creating a Lean Culture.

Yesterday, I met Nick Sarillo and he toured me through one of his restaurants outside of Chicago (here is my earlier post about Nick's Pizza & Pub). I'll write more about this in the future, but the beauty of Nick's success is that he's learned from many different sources and he's synthesized it all into a system that works for him (and it's not textbook Lean… it's just very similar to Lean since it comes from roots like Peter Senge and systems thinking).

Going back in time, Toyota learned from others (Ford, Deming, U.S. grocery stores) and they SYNTHESIZED it and improved upon what they had learned. Toyota didn't blindly copy anyone. Many organizations have struggled when they try to copy Toyota's tools (or cherry pick a few). Hell, even General Motors struggled to truly become Lean and they were working side by side with Toyota for 25 years at NUMMI. GM did some great work at the factory level, but it didn't transform senior leadership's approach. GM couldn't copy Toyota — and they shouldn't have copied blindly either.

Jim Womack wrote recently about how the Lean movement needs to quit just copying Toyota. No longer should we do things “because that's what Toyota does.” Enough of the copying, I agree. We need to do what works (based on our own evidence) and we should be willing to invent (not just copy).

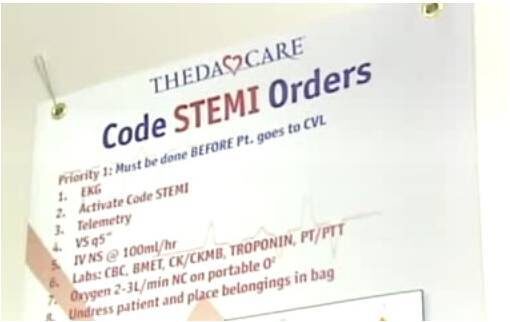

As I've written about before, Toyota was very willing to let competitors come through their factories because the visitors wouldn't see the important stuff – the “soul of Toyota.” You can't see culture and philosophy and management systems in a short tour. You SEE tools, so people tend to copy tools. That won't make you Lean. ThedaCare will let you come visit (if you bring your CEO) but don't expect to simply copy what you see. Copying their standardized work size for Code STEMI patients, the one that hangs in each emergency room bay, doesn't mean your door to balloon will instantly drop, without any effort.

So please, please, please — read On The Mend. I think it will be helpful. LEARN from what ThedaCare has done, but don't expect to copy them exactly. Learn from ThedaCare. Learn from your local example of Lean Manufacturing excellence. Read some books. Encourage your leaders and employees to experiment and PDCA. Take some risks and invent some practices of your own. Above all, synthesize and make sure it FITS with your culture and your people. There's no reason to completely reinvent the wheel, but you shouldn't blindly copy either.

I think that's the only way to be successful. There is no instant pudding for Lean.

My fear is that with a lot of copying of ThedaCare will come a lot of mediocre or failed Lean efforts that don't measure up to ThedaCare's. Healthcare organizations might give up on Lean, meaning their patients and employees won't benefit. That would be a real shame.

You can download some previews of On the Mend from this page on the LEI website or via the links below:

- Foreword from the Publisher, by Jim Womack

- Introduction, by John Toussaint and Roger Gerard

- Chapter 2: Focus on the Patient

You can also read the impressive endorsements of the book, including that of Dr. Don Berwick of the Institute of Healthcare Improvement — now the Obama administration nominee to head CMS – Medicare and Medicaid.

“We need health care that is sustainable and excellent – both. That will require rethinking our work and redesigning our systems of care boldly and guided by proper theory. These authors are masters of the change we need; under their guidance, ThedaCare has become a bright spot in the landscape of American health care. Their work and this book show that lean thinking and true patient-centeredness are not just compatible; they are, at heart, the very same thing.”

– Donald Berwick, MD, MPP, FRCP, President and CEO of the Institute for Healthcare Improvement

If you have any comments about the On the Mend material, feel free to post them here. Of course, you can comment on the “don't copy” plea, as well.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

If we copy, it is usually someone at the top or an engineer somewhere who has discovered and delivered a solution. It is a kind of command and control model dependent on compliance. It is difficult to sustain in practice and, more important perhaps, it doesn’t prepare the organization for the next challenge or the problems YOU may have that ThedaCare did NOT have.

On the other hand, if we, as an organization, learn to see our work through new eyes and to improve, the change belongs to everyone. Taking inspiration from ThedaCare (or Toyota, or the pizza shop on the corner), learning a new way to manage and solve problems, learning principles that apply anywhere, allows for change that will belong to everyone and prepares us for the next challenge. There will be one!

Learning and creating as an organization doesn’t get us perfect solutions on the first pass but I’ve come to understand that the imperfect solution that belongs to the people who do the work is the best possible outcome.

[…] Read this Book – But Don’t Copy ThedaCare dal Lean Blog di Mark Graban: On The Mend libro sulla sanità di dr. John Toussaint di ThedaCare e l’avvertimento di non copiare gli strumenti ma di costruire sistemi per le vostre esigenze imparando dagli altri i principi… (traduzione automatica) […]

[…] many times on this blog – go and learn from others, but don’t copy. I’ve even said this loudly about ThedaCare as much as I admire them (and they […]

[…] Other organizations don’t have to copy it exactly. We can learn from others, but adopt and adapt to our organization. It probably wouldn’t be helpful if an organization went to visit ThedaCare and came back to do “the ThedaCare Production System” at MidWestRandom Health System. ThedaCare people say you can learn from, but don’t copy. […]

[…] Does it mean there are serious problems and they shouldn’t be considered a leading “Lean hospital” to learn from and emulate (but not copy from). […]

[…] Read this Book – But Don’t Copy ThedaCare […]

Comments are closed.