Neatness Counts at Kyocera and at Others in the 5S Club – WSJ.com

I'm going to violate a rule I have to try not to blog when I'm frustrated or angry. Here goes…

Today's front page (argh, front page) article in the WSJ probably does more to give 5S a bad name than anything I could imagine. Of course, people don't read newspapers anymore…. but articles like this will make laughingstocks of those of use who try to teach “real 5S” not “LAME 5S” (or Lean As Misguidedly Executed). Remember this from the UK? This article brings us more 5S insanity.

It's too bad the WSJ couldn't have bothered to call Jim Womack on this (instead of calling him for every auto industry article), because I bet he would have set them straight.

I'll try to defend the good name of the TPS and Lean practice of “5S”:

Hey, neat freaks with nothing better to do…. quit telling me what family photos or knick-knacks I can have on my desk. You're a waste of a paycheck, you people who want to depersonalize the workplace. You suck. “5S Cop”? Get a real job title, something that adds value to customers and isn't just a corporate drain on shareholder resources.

That's obviously not what Womack would have said. That's what I say. And I'll stand by it. Maybe the WSJ will start calling me for interesting quotes.

Here is the WSJ video:

The article gets off to a decent start, with a stock description of 5S:

5S is a key concept of the lean manufacturing techniques that have made makers of everything from cars to candy bars more efficient. The S's stand for sort, straighten, shine, standardize and sustain.

Notice how they said “more efficient.” That's supposed to be the key point — efficiency, not neatness. Or maybe, better yet, effectiveness.

I wish the WSJ had belabored the point that 5S is about identifying and eliminating waste, not being neat freaks for neatness sake. But then they wouldn't have been able to document the corporate (and hospital) buffoonery that's in the rest of the piece.

The article then starts to talk about the new “corporate initiative” that starts terrorizing people into having neat desks:

Kyocera's version of 5S, which it calls “Perfect 5S,” not only calls for organization in the workplace, but aesthetic uniformity. Sweaters can't hang on the backs of chairs, personal items can't be stowed beneath desks and the only decorations allowed on cabinets are official company plaques or certificates.

You can't hang sweaters on the back of chairs? What? Where are people supposed to put them? A taped off section of drawer labeled “outerwear”?? Wouldn't a bigger reduction of waste involve NOT running the A/C so cold inside that people are forced to wear sweaters in July?

Not having a personal item on your cabinet is supposed to “impress visitors.” What? The only impression that it would make on me is “this is a cold, heartless, impersonal workplace…. I bet the employees are beaten down and don't put much effort anymore into quality… just survival.”

An “expert” (a “leadership expert” — where do they find these people?) chimes in:

While that may sound authoritarian, it's not the initiative that's important, it's how managers communicate it, says Gary Hayes, managing partner at Hayes Brunswick & Partners LLC, a leadership advisory firm in Bronxville, N.Y. “If managers clearly explain why they're doing something, I think most people will understand the rationale. But if you say, ‘We're doing this because 14 efficiency experts say it increases productivity,' then it becomes kind of Dilbert,” he says, referring to the comic strip of satirical office humor.

Authoritarian?? You betcha!!! I don't read much of anything in the article about explaining “why” desks need to be clear (other than the spurious “visitors” reason… what if you work in an office with no visitors?). Of course it's more than “kind of Dilbert.” It's Dilbert, absolutely. And it's L.A.M.E.

Mr. Brown, the manager of Kyocera's production technology center, has tried to inject some humor into the process. He recently posed for a photo wearing a white T-shirt and flexing his biceps, Mr. Clean style. The picture will be posted to the company's internal Web site along with tips on maintaining a clean desk.

Mr. Brown is a waste of a paycheck. Sorry if that's not keeping with the “respect for people” principle of Lean. It's probably not Mr. Brown's fault. He's just following orders from corporate. The insanity must stop somewhere, though.

Mr. Brown targets employees who dare hang seasonal decorations (it's worse than the political correctness people who don't want to you hang “Christmas” decorations).

Mr. Brown and Kyocera further waste time by focusing on “5S compliance scores” (oh, yet another distraction from actually paying attention to serving customers, improving quality, and making money):

Employees in the main Kyocera office have been pretty good, achieving a total 5S compliance score of 88.9%. But people in the wireless-phone division in La Jolla haven't been as quick to embrace 5S. That division showed improvement during a separate audit the prior week, but it scored just 61.1%. “They're more loosey-goosey,” Mr. Brown says. “They bring their surfboards to the office.”

There won't be much solace when a company goes under and their corporate obituary reads “but they had really clean desks…..”

In case anyone misses my point — I'm not anti-5S. I used 5S in manufacturing. I teach it and help implement it in hospital and healthcare settings. It's a wonderful tool, but ONLY for the sake of improving operations.

If tools and supplies are hard to find — let's say, nurses are searching around the clinic for one of the few available thermometers…. the 5S solution would include making sure the tools are available where needed (in each exam room, which might involve spending $$$) and that their standard location is standardized and clearly marked and labeled.

Jon Miller of Gemba Panta Rei disagreed with me on this (and I respectfully — emphasize respectfully) disagree with him. In my book, I made the case that 5S shouldn't go overboard or be taken to extremes. I made the point that a heavy printer that sits on a cabinet is not likely to go missing, get moved, or get lost. So why put tape around it? My argument is that there's enough “Real Waste” to be found and eliminated that putting tape around a printer trivializes 5S and seems silly because it's not solving any problem (the printer never goes missing).

Virginia Mason Medical Center (seen as one of the leaders in Lean Healthcare) is using 5S… for good and for what might be a bad application:

After Virginia Mason Medical Center in Seattle implemented 5S in 2002, doctors, nurses and assistants now share desks grouped in pods so they can work more closely together and reduce the time they spend trying to find one another. That means each person is expected to keep his desk neat because someone on the next shift will be using it.

That's great — reduce the time spent trying to find one another, that's solving a problem. When people share desks or workplaces, the idea of keeping things in standard, consistent locations makes A LOT of sense. But when it's a single employee using their own personal desk (as at Kyocera), then it makes less sense (unless you plan on firing that person and replacing them with an interchangeable cog… no, not a good idea).

But some other VMMC practices make me think:

Employees created new places for everything to eliminate the need to hunt for things. But doctors and nurses in Mr. Boze's pod kept hanging the stethoscope in its old place on a hook, instead of putting it in the drawer marked “stethoscope.” “Eventually,” says Mr. Boze, “we had to remove the hook.”

I could challenge this approach — if a stethoscope is used very frequently (and it is, which explains why it hangs around most doctors' necks — that and for a status symbol identifying them as docs), then the stethoscope should be EASY to reach. Why dig inside a drawer? Maybe it should be on a hook where it's easily accessible? Of course, that violate some requirement (who gets blamed for this frequently — the Joint Commission) that says things have to kept put away because patients might hurt themselves. Might be, but “removing the hook” seems top-down authoritarian.

It should be no surprise that your typical non-Lean command-and-control organization would LOVE 5S because it gives them another authoritarian thing to beat up employees about. CLEAN YOUR DESK!! Um, how about you give me an organized workplace and the tools to allow us to better serve customers? NO CLEAN YOUR DESK — CLEAN EVERY NIGHT…. CLUTTER — VERBOTEN!!!

We can do better than this. Those of use who have used 5S in constructive ways need to speak up about how 5S helps employees, rather than belittle them or antagonize them. Share your stories… let's share the real stories of how 5S helps…. what do you have?

And if you're Mr. Brown (or someone like Mr. Brown) who is offended and won't read the Lean Blog again…. I'm sorry. Go tidy up your desk.

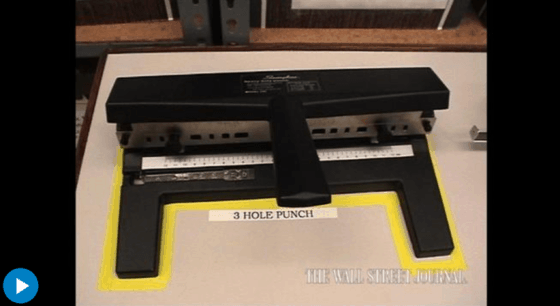

Updated: There is a video that actually gives a decent explanation of WHY factories would use 5S (waste less time looking for parts). There's one example in the video of what I think is an error. There's a hole punch in a copy room with tape around it. That's OK, if the hole punch can be moved. But when they pick up the hole punch, you just see a tape outline… so what was supposed to be there? All we see is that something is missing. Instead of putting the label on the hole punch (who doesn't know what that is??), put the label on the table space, showing where it goes. It should be done in the way that's shown in the “freeze frame” photo of the video that shows before you hit play, not the way it was done in the video with a different item.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

If you’re a WSJ subscriber online, read the comments:

LINK

The phrase “Neatness Nazi” came up quickly in their discussion.

Neatness Nazis indeed. As they say, the first one who brings up Nazi or Hitler in an online discussion is the loser.

How does the American branch of a Japanese company get 5S so wrong?? Does Kyocera do it this badly in Japan??

NO no, you *should* blog more when you’re angry.

What great reading. You said everything I screamed while reading this in paper form while my PC was booting up this morning, ha ha.

The saddest part of the video is Mr. Brown commenting on the correct # of push pins to put something on a bulletin board. He’s right, I do laugh at that.

The Training Within Industry blog also covered this:

LINK

Hi Mark,

I blogged in fury this morning as well at the TWI Blog.

I threw out the 5S Nazi term as well and I mean it like the Soup Nazi ;)

I’d like to offer one point to the discussion: all 5S activities should be done in order to SOLVE A PROBLEM. To go one step further, 5S is a simple method to use in getting people to think about little problems everyday and how to make those things better.

Neat-freakin’ activities published in this article SOLVED almost NO problems of any useful value to the people being subjected to this dehumanizing version of 5S.

5S is not a housekeeping program. If 5S is the foundation of Lean Manufacturing then that means cleaning is the core to continuous improvement?

Bryan

And some other links:

Gemba Panta Rei

Elegant Solutions

Absolutely infuriating piece in the WSJ. Thank you, Mark, for your comment on the WSJ site and your angry blog. Sherry Gordon was to the point in WSJ comments, as well.

If it doesn’t make work easier, if it doesn’t serve the needs of the frontline employees as they create value for customers, it isn’t “lean”.

I say it all the time in training here – 5S is not about being neat or complying with a set of rules. Though these may be outcomes, they are not the purpose! It is about making work safer and easier for employees and making it easier for anyone to see when things are going wrong so we can solve problems.

Stuff like this causes me to reflect on some of our institutions – WSJ and business schools, e.g., that are such an influence on managers and management. They are part of the problem more often than part of the solution!

Thank you Mark for the “angry blog” that I actually think was well written and to the point. Although we obviously focus on the 5S concepts, I believe that there is something more troubling in the corporate practice at Koycera. It is the extremism and the fact that they can get so many people to follow these rules without mass attrition that one would expect (maybe it’s happening and we don’t know about it?).

The association insinuated, in the blog’s comments, to the Third Reich are not surprising since that too was a case where extremism was practiced with a great following (and we all know the results). So not only is this senseless and not in line with Lean Thinking – it is a form of extremism that has no place in modern business nor in the world we live in!

Dan Markovitz (TimeBack Management — stay tuned for an upcoming Podcast with him) wrote about this on this blog:

TimeBack Management Blog

You should really try to use your LinkedIn network to track down Mr. Brown so he can defend himself in a podcast interview, Mark!

5S, as with visual management, is done not to SOLVE problems but to EXPOSE them.

Deviation from 5S (or from any standard) is a problem. Simply doing 5S is not a solution, since lack of neatness is rarely the root cause.

In that sense, the WSJ article has been a very effective “5S” of 5S approaches and methods.

Jon, that’s funny about the WSJ exposing the problems with Kyocera’s 5S…. good line.

I agree that, once implemented, 5S and visual management is about exposing problems.

But, the whole process of starting and implementing 5S (including sustain) is “solving” problems (ok, countermeasuring) since the problem of “things get lost or go missing” often goes away because problems are exposed in the new, more organized environment.

bowling in the office aisles doesn’t make a company good and neither does having the right number of push pins on an announcement. on the other hand bowling in aisles is a lot more fun. i’ll bet kyocera has a tuff time recruiting and keeping new grads.

When’s the last time you saw a Kyocera cell phone?

I rest my case.

This company is focusing on all the wrong things.

[…] way, including marking where your keyboard, phone, and computer monitor go. You might also remember my criticism of Kyocera’s Office 5S program from […]

[…] This WSJ Article (as do Many Organizations) Misses the Point of 5S […]

[…] with the recent “office 5S” story, is the WSJ highlighting Meijer’s practices because they’re funny and absurd, or […]

[…] cynicism and negativity on a different Lean topic from yesterday afternoon, scroll down or click here. Be warned, the article I blogged about made me very […]

[…] There are many good examples in the article, so I won’t try to quote from them all, click on the link and take a look. The article is also (thankfully) free of any really misguided sounding “fake lean” or “L.A.M.E.” practices, so it sounds like there’s a lot of good Lean work going on without too many “office 5S” type debacles. […]

I had a chance to ask a few questions of a Kyocera person with knowledge of the program:

My questions (and their responses):

Q: Is this initiative still active?

A: We have quarterly audits in both the production and office areas.

Q: How does Kyocera gauge the benefits of this program?

A: We don’t measure the benefits per se as those were understood when the program was launched via our corporate operations in Japan.

Q: What was the impact on staff morale scores?

A: I’m not sure what you mean by staff morale scores.

I asked a follow up:

I’m referring to any surveys about employee satisfaction. It seems things like saying “no sweaters on backs of chairs” would harm employee morale while having no benefit for customers.

Response:

“We don’t have surveys. We also do allow sweaters on back of chairs as well as some other comfort items we allow after feedback from the employees.”

So this sounds like a top-down program from Japan… without any well communicated benefits other than “you have to do 5S.”

I still don’t see how this benefits customers one bit.

[…] remains confidential) recently saw me reference an old blog post on Facebook. I had posted a link to this old post about Kyocera’s “Lean Office” initiative that focused on neatness and, among other things, said employees could not hang sweaters on the […]

[…] and leadership and when that improvement is connected to a mission that matters. Being told you can’t have a sweater on your chair or a waste basket at your desk – people hate that because it’s not Kaizen – […]

I used to work for Kyocera, a PCB design company. They forbid us to listen to music while designing even at nightshift. As they lose employees due to all the strict rules they imposed, their solution is to forbid us to bring our mobile phones in our desk. They said it is for security reasons but we all know, its goal is to minimize phone interviews from competing companies.

[…] Lean office initiatives should solve real problems that matter for customers and employees (not create situations like this) […]

[…] Lean is not about banning bananas from people’s desks or banning sweaters hanging on chairs. […]

[…] This WSJ Article (as do Many Organizations) Misses the Point of 5S […]

I sometimes ask about the zeroth “S”: What value Stream are you supposed to improve? In knowledge work, the gemba is people’s brains and their conversations. Remove unneccessary clutter there. Have a place for everything. Tidy it up. Like, for instance, removing unneccessary management levels, or unneccessary office rules…

[…] My friend, Mark Graban, broke one of his personal blogging rules and wrote while he was mad. You can check it out by reading This WSJ Article (as do Many Organizations) Misses the Point of 5S. […]