Here is a great article about how a company has implemented lean to improve safety. Concepts like 5S and waste reduction go hand in hand with ergonomics, safety, quality, and productivity. Oh, and this company is from the construction industry, even.

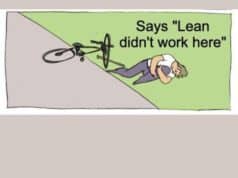

However, if a work site is cluttered and disorganized, training on poor lifting technique and proper body postures can fly out the window. That's one reason why Walbridge-Aldinger has adopted Toyota's lean manufacturing philosophy.

The philosophy involves identifying and reducing waste – such as overproduction, waiting and transportation – and adopting a system of workplace organization and visual controls known as the “Five S's.” Loosely translated from Japanese to English, the Five S's are: sort, set in order, shine, standardize and sustain.

As an example of how the principles of lean manufacturing have enhanced safety – and minimized sprains and strains – Clabaugh pointed to an “old way of doing business.”

“We'd have a laborer carry two 5-gallon gas cans out of a C container or storage area and walk the distance of the job site and walk down a ramp into a construction pit to fuel our equipment,” Clabaugh said, noting that lifting and carrying the gas cans for such a distance posed the potential for sprains and strains or, at the very least, discomfort.

Using the principles of lean manufacturing, Walbridge-Aldinger purchased four-wheel carts from Home Depot and secured the gas cans to the cart, allowing workers to pull the cart from the C container or the storage area to the work area.

Notice how they used simple off-the-shelf solutions, sort of like the parts trays that Toyota bought from Wal-Mart down the road from the new San Antonio factory.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

[…] couple other resources about Lean and safety: IMEC.org’s .pdf on Lean and Safety LeanBlog.org blog post connecting Lean and Safety Another blog’s post about “What is safety?” Lean-safety.blogspot.com – […]