In my Assembly Magazine monthly column Leading Lean, I chose to address in December one of my favorite topics, PDCA or Plan-Do-Check-Act. This is the practice of learning through improvement. I hope I did it justice, at least as much as can be done in 600 words. The column is titled The Little Engine that Could because PDCA is not the big sexy lean tool like kaizen or hoshin kanri. It's a simple concept, but one that if you keep chuggin' along with it, will deliver outstanding results.

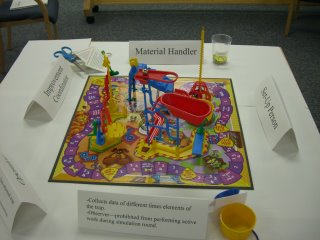

I believe so strongly in the importance and value of learning PDCA effectively that we created a package to help people teach it. This is also our FIRST product intended to be off-the-shelf and by early estimates will be very popular with lean champions and educators all over. It is called The Mouse Trap Experience where we use the popular board game to explore the concepts of PDCA and experimentation. It comes with a PDF of the Participant Guide and full Facilitator Guide including setup and running instructions, along with all the materials needed. It's basically an out-of-the-box turn-key solution for teaching a 2.5-3 hour PDCA module. Let us know what you think – pick it up here.

I believe so strongly in the importance and value of learning PDCA effectively that we created a package to help people teach it. This is also our FIRST product intended to be off-the-shelf and by early estimates will be very popular with lean champions and educators all over. It is called The Mouse Trap Experience where we use the popular board game to explore the concepts of PDCA and experimentation. It comes with a PDF of the Participant Guide and full Facilitator Guide including setup and running instructions, along with all the materials needed. It's basically an out-of-the-box turn-key solution for teaching a 2.5-3 hour PDCA module. Let us know what you think – pick it up here.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Nice column, Jamie. We’re still a “get rich quick” society, both in business and general society in this country, I think.

One of the problems with “check” is that, in so many workplaces, it’s not OK to fail or to be wrong. We often spend so much time justifying past decisions as “success” rather than being willing to openly admit a mistake and correct course.

Not to get too political, but notice how it took a new Secretary of Defense for our government to admit we’re not winning the war in Iraq.

How many times do we have a failed business initiative where leaders try to save face and declare “mission accomplished.”

That’s what our “MBA president” seemed to do. I voted for W. twice and I have an MBA, but I still think our experiment with an “MBA president” has failed. Not that Carter, an engineer, did any better.

For PDCA to work, we have to create work cultures where it truly is OK to take reasonable risks, fail, and learn from them. We can’t just cover up our problems or just hope they will go away so we can get promoted (or re-elected).

Yes, you are absolutely correct. The fear of failure is a huge barrier to organizational experimentation. If you are going to do something new, are you SURE it will work? Absolutely not, because it’s new. If you only did the stuff that you KNEW would work, then you would never move forward. Inherently, an organization that fears failure will also fear progress. Alas, far too many organization fall into that catagory.

That being said, that does NOT mean individuals shouldn’t be doing it. Here’s how I know this. People end up doing things every day (solving problems for example) that they DO NOT KNOW the result. However, they are not treating what could be an experiment as one, and the result is lost learning opportunity. We’re all doing new stuff – how we treat that work determines what we learn.