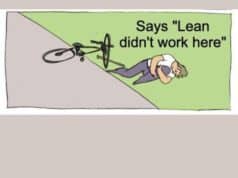

I can't think of an industry that could use lean or “process thinking” any more than the home contractor industry (ok, well maybe healthcare).

I'm currently having a gas grill bricked in out on my back patio and I've been working from home this week to see how the process is going.

On the positive side, the four guys who are actually building the stone exterior for the grill island are doing amazing work. The craftsmanship of hand cutting/chipping/chiseling that stone into pieces that fit into the structure is incredible to watch. I've talked to them (the best I can with the language barrier, me not speaking Spanish) and told them “good job” the best I can. You can see the pride in their work, which is great to see.

Now, the “professionals” on the management side of the contractor house is a different story. Miscommunication and dropping the ball has been far too commonplace. I've had to micromanage and correct many phases of the work — a job that I assumed I was paying the contractor to manage details of. For example, I need a gas line run and I identified a contractor to do that for me. I could have called the guy to schedule it but my contractor volunteered to do it for me — but he didn't and he ran off for vacation out of cell phone range for the weekend. I found this out because I called the gas line guy myself (a 90 second call I would have been happy to make…. and would have done) and he hadn't heard anything yet. It's not really going to delay the project, but it's annoying and a “waste of the customer's” time as Jim Womack would say.

I believe that the contractor wants to do things right — but, as with building a house, “doing it right” seems to involve a lot of rework rather than precise planning. It should be cheaper to do it right the first time — “plan slow to go fast” as Toyota might say.

I will give the contractor one piece of credit — they were digging out the foundation and it seemed very deep, even given the shifty soil here in Texas. The contractor said that they've learned to spend a little more $$ on digging and concrete to do it deeper — it ends up costing them less in the long run to avoid cracks or problems that they have to come back and fix after the fact.

So, from a physical construction standpoint, this contractor has learned that it's indeed cheaper (and less hassle for the customer) to build in quality. Too bad they haven't learned to do that from a business process and communication standpoint. I've see this trend repeated too many times — skilled tradespeople (like a plumber who recently repaired a water heater) who are good at “what” they do — but horrible at running the customer-facing aspects of their business.

I might have to have a “lean thinkers” BBQ here in the Dallas area once it's all done :-)

Hope everyone had a productive and rewarding Lean week.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation: