A “shadowboard” is a common method in the Toyota Production System. It is a “5S” method where an outline or solid “shadow” is drawn behind where a tool would go on a board, bench, or table. With the shadowboard, it is easy to tell where tools go and when something is missing (a key element of visual management).

A “shadowboard” is a common method in the Toyota Production System. It is a “5S” method where an outline or solid “shadow” is drawn behind where a tool would go on a board, bench, or table. With the shadowboard, it is easy to tell where tools go and when something is missing (a key element of visual management).

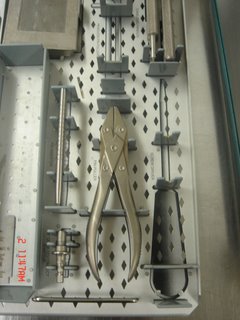

The picture at left shows a surgical kit I saw today, being prepped for pre-surgical sterilization. This is a very fancy version of a shadowboard, but you can see that the screwdriver has not yet been replaced in the lower right corner of the box (click on the photo for a larger version).

Shadowboards don't have to be so fancy. In my last manufacturing job, we wanted to mark where a heavy duty glove was stored for a production oven. The glove was laying on the right spot on the white-topped bench, so I took a permanent marker and drew an outline. Effective, albeit not real flexible if they decided the glove should be in a diferent place (kaizen). It shook the team up a bit, in a positive way, and inspired them to take some intelligent risks with some other improvements.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

At our facility we have implemented shadaow boards in our production areas, by using thick 1/2″ foam. We simply place the tools on the foam, and use a small knife to trim our the shape. Inexpensive, and it holds tools secure. In tool drawers or where space permits, you can place an extra uncut, contrasting color piece of foam underneath to make the empty tool space even more apparant.

‘Shadowing’ is very effective for an operator & manager. We have made shadow board out of card board boxes (old shipping boxes) and a black felt marker.

The problem with some shadow boards is that they’re TOO good. When I first looked at this picture, I didn’t notice that the screwdriver was missing!

My personal preference is for nice simple outlines, without any greyscale shading. That way, it’s a whole lot easier to see what’s not there.

(If that makes sense.)

I agree that simple is best!

I’m WAY more concerned why screwdrivers and pliers are being used in surgery….

That’s funny. No, it’s not dark ages surgery. It’s for orthopedic implants (like a knee or hip), so I imagine those tools are used for some adjustment purposes.

You would be very surprised, shocked or horrified (depending upon your gore factor) to see an implant or total joint surgery.

What has always surprised me about Hospitals is that they claim to be ‘special & different’ but suffer from the same process problems and terminology as manufacturing. Here is an example: In the OR the doctors refer to themselves as ‘electrical or plumbers’, they have no problem getting a chisel and hammer to “fit” the implant, etc.

We had an interview with Professor Monden who is the author of Toyota Production System. He is a professor of Mejiro University in Japan still working on Toyota Production System.

http://www.lean-manufacturing-japan.com/interviews/toyota_production_system.html