By Bill Hanover, ThroughPut Solutions

With seven children and two adults all living in the same house we have found that applying a little Lean here and there has made our lives together a lot more enjoyable.

Our laundry room is a good example of “everyday Lean.” For years we embraced “The Pile” as it was affectionately known, as a way of dealing with a significant amount of dirty laundry a family our size can generate. Maintaining the pile was easy, almost effortless, and we all grew accustomed to its trappings. One would simply throw their dirty clothes or towels etc. into the pile and mom would wash them as time allowed.

The pile, however, took on a life of its own, growing and changing shape much like “The Blob” of horror movie fame. Sometimes the pile was so out of control that just entering the laundry room was challenging even for the most advanced spelunkers and rock climbers in the family.

In truth, the pile left us wanting as we would often run out of critical items. On many occasions we found ourselves scrambling and picking through the pile at fever pitch to find and wash “out of stock” items like socks or underwear. In retrospect, this back breaking, inconvenient, and annoying task marked the beginning of the end for the much maligned pile.

On wash days, Mom, and others, would square off with the pile in a contest of wills marked by frustration and perspiration. Eventually, and after considerable effort, the pile would be reduced to several smaller piles sorted according to color and type and the washing would ensue.

When all of the sub-piles were gone, magically, without any hesitation, a new pile would begin to form as if the primordial ooze of cloth itself was perpetually self-generating into a new life form, all the while mocking those who sought to overtake it. And so it was for years; battles won and lost on both sides, but the pile always maintaining the upper sock.

Knowing something of Lean and being rather battle weary with the pile, I began to look at new strategies to gain advantage over our common foe. KanBan, as it turns out, held the keys to certain victory, but how could one apply KanBan in a laundry room and beat the pile?

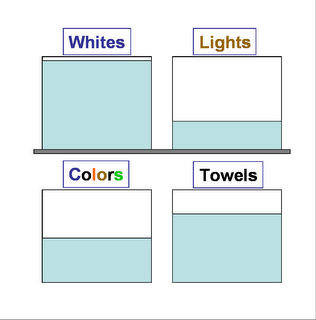

At last it came to me, and the illustration below shows the ideal state of laundry nirvana that we have enjoyed for nearly ten years.

The Layout:

4 large tubs (1 tub = 1 washer load) Two of the tubs sit on the floor and two tubs sit on a small shelf directly above the others. I made and installed the shelf with a couple of basic shelf brackets and a piece of plywood.

4 signs designating which items are to be placed in each corresponding tub (I even color-coded these for children who could not yet read)

The Process:

Every family member (except our 1 ½ year old) is expected to sort their own dirty clothes into the tubs provided in the laundry room. It's pretty straight forward really, and yes, occasionally the little ones do make minor mistakes.

Mom or Dad will ask any of our older children to “please wash a load of laundry.” To which our children dutifully reply something like “How come I always have to do it?” or something like that, but that's another story.

The poor picked-on child will then look at the various tubs of laundry and select one that is full or very nearly full and empty it into the clothes washer beginning the wash cycle. (In the example above the “Whites” are the clear winner.)

If no tubs are full the process is put-off until at least one tub becomes full.

If more than one tub is full the child is left to decide which tub to begin with (and it really doesn't matter where they start.)

Well, there it is. The system is visual and simple to use. The tubs define the proper amount of clothes for a load, and the level of clothing in each tub determines which items are to be washed and which items can wait a bit longer.

In case you're wondering, no one could load the washer unless they had first placed the clothes in the washer into the dryer; and of course, they couldn't do that unless they had likewise unloaded the dryer. As with any good process, one step leads quite naturally to the next.

The “laundry mantra” in our home is “wash whatever's full.” With just a little KanBan ingenuity and a few dollars spent at the Home Depot we managed to beat “The Pile” once and for all.

Don't ask how we've managed only having one bathroom shared among 9 people in our 100+ year old home; that is more of a SMED issue.

Bill Hanover

CCO, TPS – ThroughPut Solutions

Increasing Profits by Eliminating Waste

http://www.tpslean.com/

jb@tpslean.com

435-792-4380

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

It sounds like a good start to a laundry system, but there is a risk of catostrophic failure: What if someone puts a red sock in the “Whites” pile? Then, when the “Whites” tub is full, someone dumps the whole load into the washer, the laundry is not inspected to make sure only the correct color is going into the washer.

The result is that the whole load of whites is ruined. (unless you like wearing pink underwear).

The problem is that there is no way to inspect a whole tub of laundry at once. So, somehow an inspection step needs to be inserted.

Actually, the original method, the “giant laundry blob” had an inspection step: items were individually loaded into the washer, so every item was inspected individually.

Maybe you trust your family to place laundry into the correct bin 100% of the time. But, any quality control text book says that humans are unable to achieve 100% inspection, they always miss a certain percent of defects. So, eventually it is inevidible that you will end up with a load of pink underwear.

So, in conclusion, I am going to stay with the “huge laundry pile” method. It may be ugly, but at least I won’t have to explain to everyone at work why I am wearing a pink shirt!

Perhaps any time saved with new laundrey systems is a net loss with all the time we just spent thinking about our laundrey system. Could we focus on more important issues?

Looks like we have some critics ; – )

Hey, we’ve gone 10 years without so much as a pink sock so we must be doing something right.

Yes, even the older children that wash clothes inspect as they empty the tub into the washer. There was also training about detergents and bleech, etc. but the post could get very long if I explained too much.

I guess the main point of this “everyday lean” example is that there are opportunites for lean everywhere you look; even in the home.

As for focussing on more important issues…hmm? Could there be more important issues? ; – )

All the Best!

I, for one, think anything that forces us to think about lean issues outside of our current company or comfort zone is a good thing. There are excellent points to discuss — Bill’s idea of standard work for laundry and the anonymous concern about the lack of error proofing. Good points all. Bill, I hope you would admit that, even though you don’t have any pink clothes yet, the opportunity is there for an error to be made.

If you that reading about this is a waste of time, then posting about is, ironically enough, a bigger waste of time.

My filter for this blog has always been “is this interesting to me?” so I won’t worry about trying to make all readers happy all the time.

You bet Mark, some “errors” have happened over the years and more may still occur. It’s definitely not completely error-proofed.

There’s the occasional pen or school lunch id that get’s washed if pockets aren’t thoroughly checked, and gummy bears can really wreak havoc if they make it to the dryer! ; – )

All in all, it works pretty darn well, and we all appreciate the substantial improvement over the good ol’ pile.

Perhaps all I’ve done is broken the generational acceptance of the pile and helped my kids realize there are better alternatives to old problems.

That would be a lean victory in any household. I’ll take it!

All the Best

Hello people,

This is surendar narasimhan from india. It would be useful for me if you could throw some light on LEAN SIX SIGMA…as lean in itself is a philosophy……

[…] 2006 · 1 comment I’d like to welcome our latest Lean Blog contributor, Bill Hanover (his first post is here). Bill has been a frequent participant with the blog, posting many comments about articles and […]