Continuing on the tour (click here for previous stops), we step back into the National Museum of American History, where they had some fantastic displays of early American manufacturing.

One display case featured the rifles from the Harpers Ferry Armory, probably made around 1840.

The production process became famous for the use of “interchangable parts,” a concept we take for granted today. Before this advance, items were manufacturing as “one off” or unique items, with pieces being filed and customized to fit only that particular rifle. With advances in gauges and quality techniques, “identical” rifles could be built, where if there was a problem in battle, parts from one rifle could confidently be used to repair another rifle.

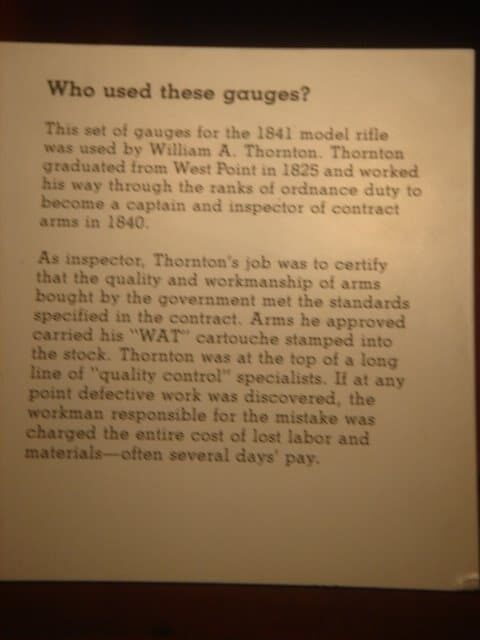

Here is a picture of some of the gauges used by workers at Harpers Ferry, along with a sign explaining more:

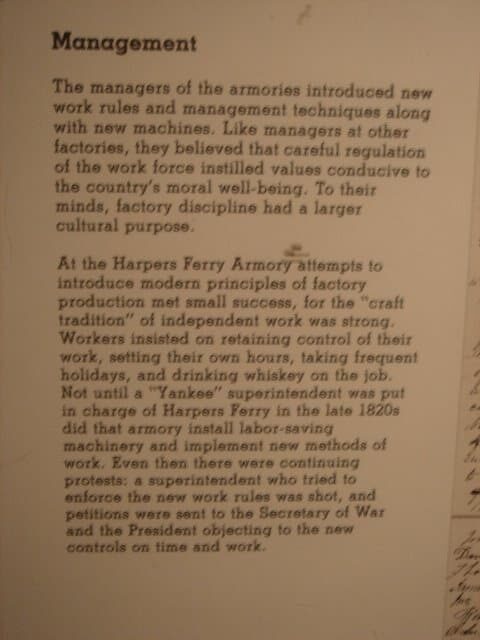

Even with the technological advance, the factory had management problems. It seems that the management approach was brought over from the military, a strict command and control structure. The workers, used to being in the “craft” system where individual workmanship was more important and structure and control, rebelled. The writer of new work rules was shot (!!!) and petitions were sent to Washington asking for change.

What work conditions did workers want to maintain? “Setting their own hours, taking frequent holidays, and drinking whiskey on the job.”

More to come…

Click here for the final stop in the tour, Stop #5.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

[…] do you think?Move on next to Stop #4 on the DC Lean Tour. Please check out my main blog page at […]