Here is my posting for the Monday “Project Kaizen” group blogging effort, the topic being “Why Project Kaizen?”

————————–

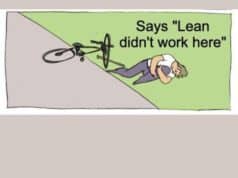

Why wouldn't the concept of “kaizen“, or continuous improvement, apply to any activity in or organization? While there are many definitions of lean, one definition that's spread by Toyota people, as well as Norm Bodek, is that lean can be defined as 1) relentless focus on eliminating waste and 2) having respect for people. In any setting, whether it is manufacturing, a business support process (such as accounts payable), health care, or a project team, these general concepts can apply and can drive success.

If you can tolerate waste, don't need to improve, and don't want to respect people, then kaizen isn't for you. Rather than asking “why kaizen”, I'd ask “why NOT kaizen?” Even if you think you have an organization that's “working well” today, you should still be driving improvements. If you're not improving, you're getting worse! By respecting people and allowing them to grow and develop, they will take pride in their work and will naturally drive improvement when given the chance. My challenge to you would be to think about how those two simple concepts apply to your project team before you undertake formal kaizen events or attempt to implement any specific lean tools.

Visit the other group bloggers:

- Bill Waddell at Evolving Excellence

- Chuck Frey at Innovation Weblog

- Hal Macomber at Reforming Project Management

- Joe Ely at Learning about Lean

- Norman Bodek at the Kaikaku Blog

- Jon Miller at Panta Rei

Tuesday: Workgroup kaizen

- Our attention will be on making improvements for sub-team members performing the same type of work.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation: