What a great time on Thursday with Masaaki Imai! We were hosted by a non-profit organization, SightLife, that has used Lean to improve the way they collect, process, and ship corneas to transplant patients around the world. It's a bit of a cliche to say that Lean allows us to see the world through “new eyes” — but SightLife literally makes that happen.

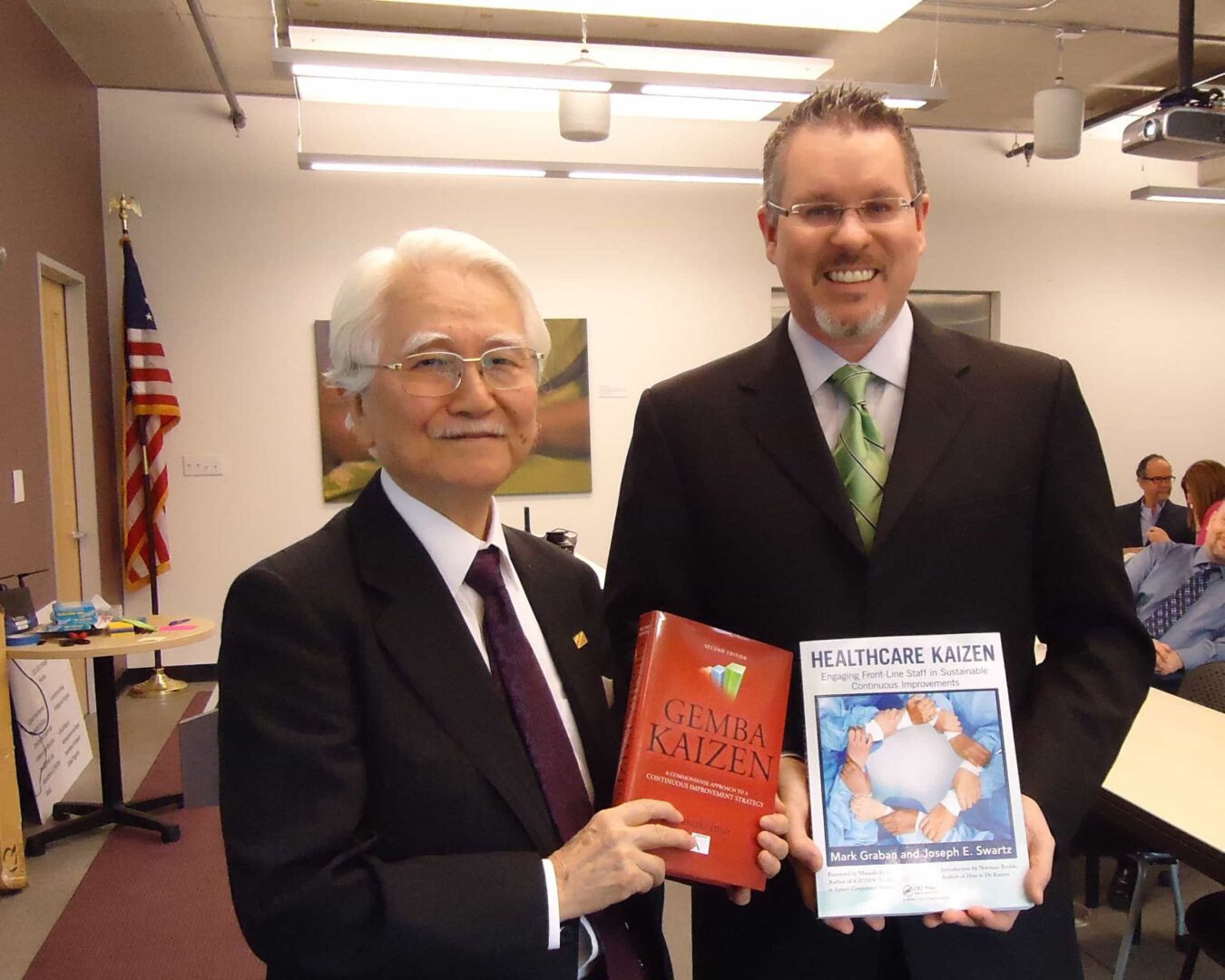

In attendance were many friends, including Brian Buck and fellow author Naida Grunden. Jon Miller and Mike Wroblewski from Kaizen Institute were there, as well (with Mike presenting). I was able to thank Mr. Imai for what I have learned from, giving him a copy of my latest book and accepting a copy of his, as seen in the picture at the bottom of the post.

Some highlights from Mr. Imai's remarks:

He emphasized that Kaizen shouldn't be viewed as “Japanese management,” but rather as “good management practices” since they are used throughout the world, in many industries.

Kaizen should be defined as:

- Everyday improvement

- Everybody improvement

- Everywhere improvement

And we shift from small incremental improvement to dramatic strategic improvement. Kaizen requires determination and self discipline.

Imai said “we're talking about a strategy to be more competitive” and that means not “beating your competitors” but rather “providing better products and services to CUSTOMERS.”

Imai noted that too many top leaders think Kaizen is a bunch of tools for the shop floor. Instead, you need to start with the top three most important things:

- Top management involvement

- Top management involvement, and

- Top management involvement

Too many companies “skip all three” he noted, which drew laughs from the crowd.

Kaizen should also be for all aspects of a company, not just the factory floor. Kaizen should be applied in these phases of an organization:

- Design

- Make

- Sell

Mr. Imai described the difference between knowledge and wisdom:

- Knowledge — you can buy it (from books or classes)

- Wisdom — you can only acquire it by practicing

He said:

“Seek the wisdom of 10 people, rather than the knowledge of one” when engaged in Kaizen.

Imai told a number of jokes and funny stories, including one about making sure standards are appropriate and that managers act properly when managing standards. Paraphrasing the story:

The plant manager was told by one employee that it was very important that they work on *this* side of the machine, because working on the other side is very dangerous.

The plant manager was at the “gemba” later and saw a worker on the *other* side of the line. The manager got furious and yelled, “Why are you working on that side of the machine?????”

The worker explained, “Because I am left-handed, and it's unsafe to work on the other side.”

Standardized doesn't always mean identical. Great lesson there (and a lesson about asking questions instead of assuming and yelling).

Imai finished by talking about the need to accept problems openly in an organization, saying:

“Problems are the mountain of treasures…. the problem is that the problems are the problems.”

He criticized that managers too often have employees learn tools like Six Sigma and then tell them to go fix problems, while those managers don't do anything to change the culture so it's OK to talk about problems. “People need to be frank about problems.”

Imai said, “It's like giving a child a pair of scissors… they are happy to cut anything.”

That criticism, I'm sure, could be applied to 5S, Lean, or other methodologies, not just Six Sigma.

Imai certainly had a lot of wisdom to share – and in a thoughtful and funny way. It was a real treat to get to meet him.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Great post. It is wonderful to meet with people that have so much wisdom on managing well.

[…] Masaaki Imai wrote about Kaizen in 1986. Dr. Don Berwick wrote about Kaizen for healthcare in the New England Journal of Medicine in 1989. […]

[…] Notes from Meeting Masaaki Imai by Mark Graban – “Imai noted… you need to start with the top three most important things: Top management involvement, Top management involvement, and Top management involvement. Too many companies ‘skip all three’ he noted, which drew laughs from the crowd.” […]

[…] Masaaki Imai will be joining us on the Friday of the week in Japan. […]

I remember a while back seeing a great video with Mr. Imai in which he explained the “everywhere, everyone, every day” concept. But I can’t seem to track it down now – does anyone know where it is (if it still exists on the internet)?

Thanks!

Here it is:

Thanks Mark!!