Mark's note: Thanks to Freek Dekker for this guest post. I met Freek at last year's Lean Healthcare Transformation Summit, as he was part of a large Dutch contingent. You can now register for the 2012 Summit (move quickly, as this sold out early last year). I hope to see you there, as I will be attending and I'll be moderating the CEO Panel again.

To ‘Catch' A Crash

As I read Mark's first chapter of Healthcare Kaizen I couldn't stop thinking about the elegant simplicity of the solutions provided. Blowing wedding bubbles to keep toddlers calm… Wow! A recent incident and subsequent Kaizen in my own department came to mind. I'm honored Mark asked me to share that Kaizen with his readers.

In October of last year, a 72-year old Mr. Van Ingen was given radiation treatment for a tumor in his abdomen. Van Ingen was a very large and heavyset man who had been working the Rotterdam docks for his whole life. His radiation treatment was to take 30 consecutive days. He was quite uncomfortable with the thought of having to lie on a treatment couch for over 10 minutes each day whilst radiation was to enter his body. On that first day he had taken some medication to stay calm during the procedure.

As Mr Van Ingen was nearly 7 ft tall, the treatment couch was ‘extended' with an auxiliary fixture to allow for the tumor to be targeted from the gantry at the most optimum angle and distance. Over the last fifty years, extremely clever clinical advancements have been made within the field of Radiation Oncology. The ability to target tumors with high dosages of radiation whilst sparing healthy tissue is mind boggling and requires state-of-the art planning systems, huge amounts of computer calculus power and high precision treatment equipment. Processes, however, have not always kept up to speed with clinical innovations.

Treatment started and, once the first radiation field had been treated, the gantry of the linear accelerator turned counterclockwise to move from one radiation field to another. The extended fixture however, was directly in its pathway. The gantry crashed into the fixture with such great force that the treatment couch, which was made of carbon fiber, broke under its pressure.

Van Ingen and the technicians operating the machine were appalled. How could this ever have happened? Technicians immediately comforted the patient. Fortunately, there was no personal injury, other then the scare he had had. Apologies were made and plans to restart treatment were launched. Because the couch was now broken another accelerator was required to treat Van Ingen and all the other patients scheduled for that accelerator.

First analysis showed the rareness of the treatment setup. The extended fixture had, in hindsight, never been used whilst the treatment couch was set at an off-default angle, thus allowing for the gantry to crash into it. As with most incidents, no further analysis or action was deemed necessary. It was considered to be a one-off incident, to be better guarded against by operators the next time – to be prevented by paying even closer attention.

Unfortunately, another crash of the gantry into an extended fixture, to our leaderships' shame, happened only a few weeks later. It was now obvious we needed to adjust our way of acting. Arnold, one of the team leads, came up with a plan: “let's get a team of technicians, engineers, physicists and builders of medical devices together and let's see what we can do to prevent this from ever happening again”. It was one of the breakthrough moments in our lean journey so far, setting up a team of people with very different backgrounds and knowledge into their first Kaizen.

As the team got together at both the broken down treatment couch and a working one for comparison, several ideas were put forward. Some were discarded for practical reasons. Being on site made it fairly easy to see what was doable and what was not. Arnold reflected: “we used to have bi-weekly meetings in a conference room around problems like these, and the process would end up in us having to pay better attention next time….”

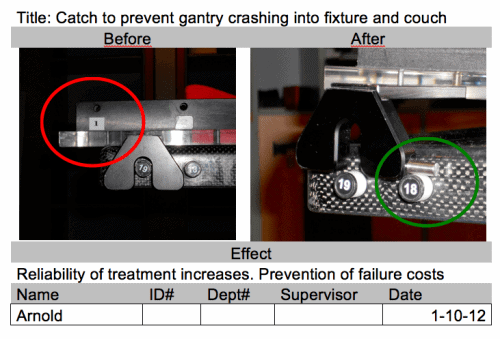

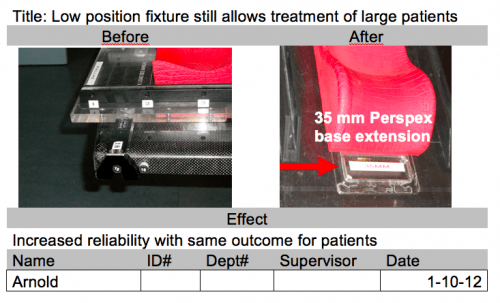

One of the ideas the device builder came up with was to apply a small catch, preventing the fixture from being inserted into the slot that would extend it from the treatment couch. However, that countermeasure would make it all but impossible to treat large patients, but the team decided to elaborate on the idea anyway. Was there a way to ensure the treatment of large patients without having to extend the fixture from the couch? An additional improvement was thought up: the arm support, which was stationary on the fixture, would need to be movable to allow for the arms to be rested in the highest possible position.

Our device builder created a prototype, as thought up by the team. In the same week, the team decided the improvement could be put to the clinical test on one machine and, within another week, after a few alterations, the test was extended to the rest of the machines within the team.

Every clinical or process innovation was finally presented to the leadership. As the kaizen was acknowledged and applauded, a newsletter to the other teams was sent out. Since then, all of the 12 linear accelerators have been adapted with the new fixture.

Mr. Van Ingen or any other patient can now be assured, even for off default treatment types the countermeasures put in place will ensure a better and safer treatment!

About Erasmus MC

Erasmus MC is the largest en most versatile university medical center in the Netherlands. Erasmus MC wants to further extend its international reputation and become one of the twenty best medical institutes in the world by 2013. Primary focus is on patient care, education and scientific research. Erasmus MC has a 1 billion Euro (appr. 1,3 billion $US) turnover with 14.000 staff. Every year 38.000 patients are admitted, 504.000 outpatient visits are serviced, 18.500 surgeries performed and 16.000 research publications published.

The Erasmus MC Radiation Oncology's Dept. Lean journey started out in 2009. Entry waiting lists were increasing due to lack off staff operating the linear accelerators. After visiting a paint factory (!) and through a lean improvement program full capacity is now in use with the same number off staff. Treatment capacity has even been enlarged by opening a second site.

Last year management decided to increase lean efforts to Erasmus MC Oncology as a whole. Teams are now working to shorten lead-times in clinical pathways and research programs. Wards and outpatient clinics are introducing daily stand ups and improvement walls to support a culture of continuous improvement.

Company website: www.erasmusmc.nl/?lang=en

Blog by Freek Dekker: www.leanliefenleuk.blogspot.com (partially in English)

Names and details have been altered or made up to allow for patient confidentiality.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

An excellent solution, and a great example of improvement.