One of the things I like about working at the Lean Enterprise Institute might seem like a silly thing — it's that I get to actually be the USER of a simple kanban system.

I've helped factories and hospitals set up kanban systems, but then I walk away and don't get to really live them day-to-day. As an aside, early in my career *I* made the kanban system — this was a mistake, even if it was a technically correct and workable. (Update: I write about this in my contribution to the book Practicing Lean).

I learned that it's far more effective to teach the kanban method and then let the actual users of the system set it up and own it. They learn more and it's all-in-all a better approach. Teaching them to fish rather than giving them a fish, if you will.

In this post, I'll give a quick example of how our simple kanban system works at LEI. I didn't set this one up, I just get to use it and I benefit from it since we always have the coffee or tea I want.

Many of our office supplies, including “K-cups” for coffee and tea, are on a simple kanban card system. My understanding of the history pre-kanban is that the office would sometimes run out of items. That doesn't happen with the kanban system. Is that really a core issue in our business, making sure we don't run out of tea? No, but managing with kanban is easier than the other informal ways of managing supplies.

As another aside, the commercial Keurig coffee maker is a “single cup” machine, meaning the beverages are always fresh and we never have a scorched pot of empty burned coffee sitting there. Per cup might be more expensive, but the variety of flavors and freshness are a big plus (which is why we use one at home.

So, the other day I went to make a cup of tea in the afternoon (I drink coffee in the morning, if you care). I took the last K-cup. so there was an empty box:

Being a conscientious employee, it was time to use the kanban system!

I took a few steps to the left to the cabinet where coffee/tea inventory is stored. When I took the box, there was a blue kanban card sticking out, as this represented the re-order point. An alternative and common kanban setup would be to stack the two tea boxes on top of each other on the counter, but that would take up more space than our current setup.

I put the new stock in place (as I would expect other colleagues to do):

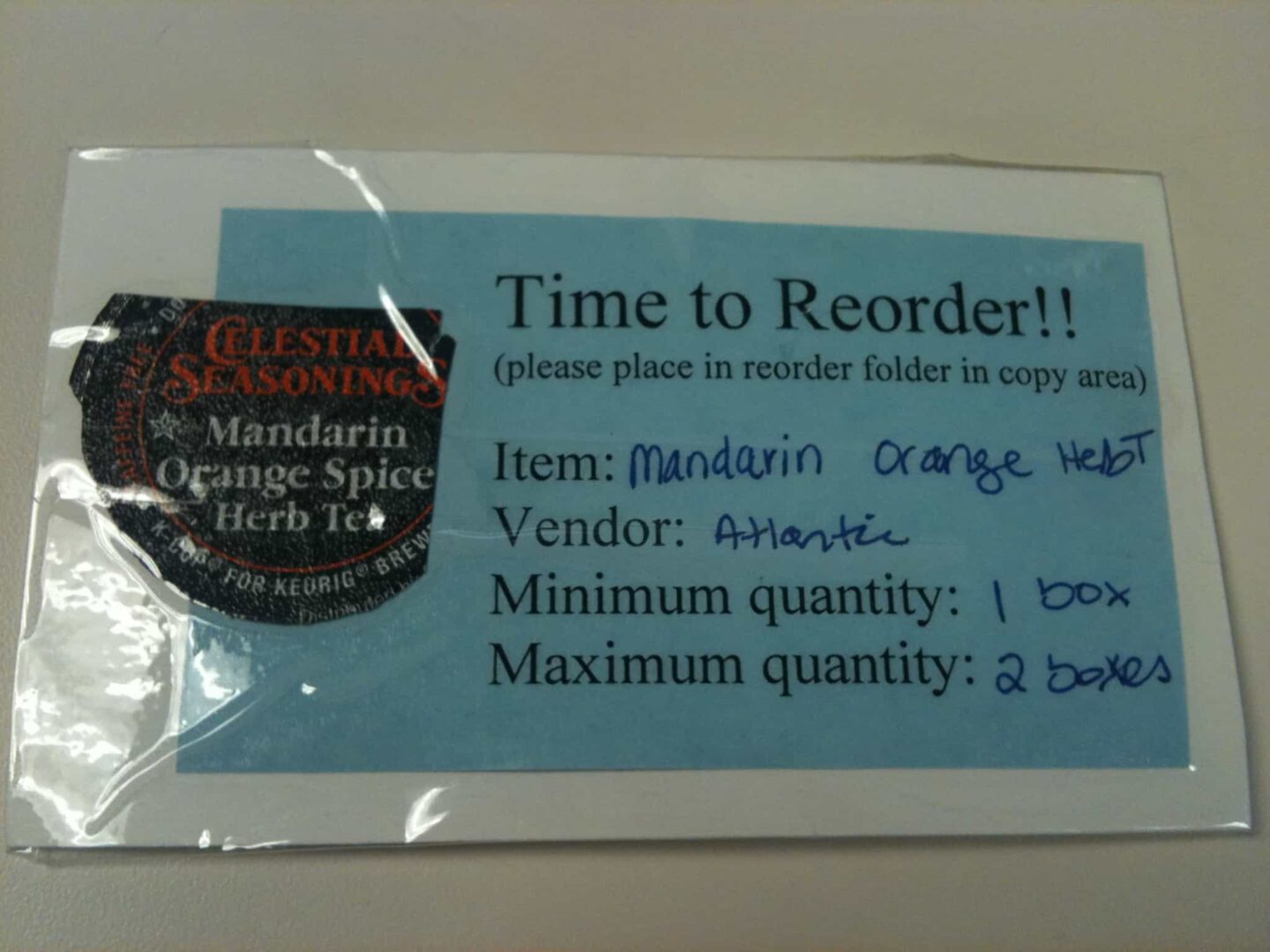

I then had to take the kanban card, pictured below — it's a simple design, an index card with scotch tape over it. Nothing fancy — it works.

My remaining job was to walk the kanban card to the front reception desk, placing the card in the designated spot, as pictured here:

That came out a bit blurry on my iPhone. The top holder is for the supplies that need to be ordered. Down below are the cards for items that have already been ordered (this prevents double ordering). Jean, a wonderful person who is usually the voice of LEI when you call the office, places the order to our distributor/vendor. When new stock arrives, the cards are taken from the bottom holder and are matched with the inventory when it's put away.

That's it. Simple.

Many of these items, in situations like this, are a simple “2-bin system” – meaning there is a second bin (the full box of K-cups) to be used once the first bin is empty. The empty bin is the reorder signal and could possibly serve as the kanban signal itself. You could tear part of the box to use as the kanban card for Jean.

In setting up a system like this, you just have to be careful that the 2nd bin has enough inventory to last you until the new stock arrives. If you order weekly and the material arrives the day after, the re-order quantity really needs to be six days worth of supply. Let's say you order every Wednesday and a kanban card is delivered RIGHT after the order went out, the card might sit for a week until a new order goes out (or maybe the order gets modified if it was just put in).

Two-bin systems often work great. I use it at home, as I've blogged about before. If you want to make sure you don't run out of things, just have a 2-bin system. The extra inventory and space is often very minimal. Who wants to have the shaving creme can empty just as you're looking to shave on a very important day?

Items I currently have on 2-bin kanban at home include:

- Shaving creme

- Toilet paper (2 packs)

- Dishwasher detergent

- Toothpaste

- Deodorant

Again, this simple system works. It's not the solution to world hunger, but it's a good way to practice what we preach. More important lean principles for LEI include:

- Strong sense of shared purpose

- Visual management

- Standardized work

- A culture of kaizen / PDCA

But we like our kanban system. Have you done something similar in your office?

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

Well, on your “teaching them to fish”:

I think I found in Taiichi Ohno’s books the pretty wise sentence “Teach the questions, not the answers”.

The good thing with this approach is the WAY higher acceptance your solution receives, when your client “invented” it him/herself.

Great to see you guys all practice what you preach! :)

My girlfriend and I have just moved in together and we keep milk, sugar, teabags and coffee on a two-bin system. I’ve been preaching lean to her for the last 3 years and as a Montessori & Childcare Teacher she’s been giving me the parallels in her classes i.e. good 5s, kaizen and visual management.

Nerds? Yes. But the very cool kind…

Regards,

Simon.

Mark:

It’s not the office, but our ag chemical (pesticides, plant growth regulators, etc.) room from which my kanban story comes. Really this story is about understanding waste.

This room is a model in our industry, thanks to worker motivated and maintained 5S. [There’s no more compelling argument for 5S that I’ve seen than storing, measuring and dispensing hazardous chemicals.] But the individual in charge insisted on taking inventory every week and calculating the order. Shelves were even labeled with standard quantities to have on hand (half way to kanban!), but the response to questions about “why not kanban?” were “I don’t mind taking inventory” and “It doesn’t take much time”. Waste identification fell on deaf ears.

Well, we’ve had a few transitions, and a new person is responsible for the resupply. New to our organization and new to lean, but when she heard that something called “kanban” could save her an hour a week taking that inventory and fooling around in a room that is not the most pleasant (in spite of our bests efforts), she was into it – the only question was “how do I get started?”

It means “time back” for a busy person, not to mention never running out and never having more than we need.

Two bin systems at home? When I open the new bag of Starbuck’s beans and load the grinder, that’s the signal to stop in on the way to work and resupply. Some things we really can’t afford to run out of.

Great example of office kanban. Thanks for sharing.

When people ask me what kanban is, I tell them we actually have it our office. Our receptionist (who has never heard of lean or TPS) uses a visual kanban system to re-order toner for our big network printers. She always has 2 of each kind and stacks them neatly next to her desk in a very rectangular pattern. If someone takes one, there’s a noticeable gap and she knows it’s time to re-order. And because it’s all stored in area next to her desk, she has continuous visibility.

Mark, The Socratic approach to kanban is what we use at VIBCO. WE assembled a cross functional team, made sure they understood exactly what a kanban is, the purpose of kanban, and how kanban would be used to achieve our “True North”. We started small got it right, and began to spread it throught the comapany. The kanban team actually created a “kanban” station where team members can create their own cards and figure out all th information necessary to put on the cards. We monitor the kanban system monthly and adjust according to demand and history.

P.S. Great to see you again yesterday, I thought it was a successful tour.

Simon,

You (and your girlfriend) might like Robert Martichenko’s book “Everything I Learned About I Learned In First Grade”. http://www.leancor.com/index.php?page=Lean-Six-Sigma-Resources_Lean-in-First-Grade-Book

It’s a great little book and it’s exactly what the title infers it’s about :)

Great blog post, Mark! Not only do we use kanban in our office, but we use the same Green Mountain Coffee as well ☺.

We at KCOE have been using kanban in the office for several years now, to both learn the system and to eliminate waste. What we coach is first use kanban as a cultural change tool then a lean tool, i.e. getting people primed to use kanban to eliminated waste and promote one-piece flow.

It was no different in our office. I just took a walk around and here are some of the kanbans are in place around these materials:

a. Coffee/creamer/sugar

b. Blank problem solving sheets

c. Blank master plans

d. Blank suggestion forms

e. Pens, pencils, markers

f. Paper

g. Etc, etc.

About 9 months ago Ryan, our senior co-op, was put on a project to pdca all of our material and kanbans, improve and standardize them. I’m going to have him create a video blog discussing his project but here’s a brief overview:

Kanbans were triggering the appropriate responses, however the “cards” and other systems weren’t standardized. Ryan essentially standardized the kanban cards/bins/etc to contain work instructions on what needs re-ordered, where it needs ordered from (and the process behind re-ordering), and where the delivery go when they are received. Before his project whomever hit the kanban was responsible for the re-ordering. Now, there is a kanban post that staff is able to hang kanbans requesting that material be re-ordered, and the co-ops take care of the non-valued added work of re-ordering and replenishing material.

I’m going to take some pictures and post them on our facebook page http://www.facebook.com/engagingkcoe

Also when Ryan is in next week he will create a video blog of his project.

It’s amazing what you can learn in the office with generally inexpensive material and apply in the field to improve safety, quality, productivity, human development and cost.

Steven Leuschel

Coach

KCOE

[…] How a Simple Office Kanban System Works by Mark Graban – “In setting up a system like this, you just have to be careful that the 2nd bin has enough inventory to last you until the new stock arrives. If you order weekly and the material arrives the day after, the re-order quantity really needs to be six days worth of supply.” […]

Thanks Steven – here is the exact link to his kanban photos:

http://www.facebook.com/album.php?aid=167136&id=88831214009&ref=mf

Great article! I would like to use your example in an upcoming talk (with attribution) if that is OK.

Mark,

If we have 2 or 3 points of consumption of the same items in our office, and we keep a small storage of items in a closet, I guess we would put the Kanban card in the warehouse where the items are stored?

Ryan

A full kanban implementation would possibly have cards for each point of use (pulling from the closet) and then a separate kanban card for reordering from the vendor TO the closet.

Or, if the points of use are close enough to the closet, maybe no cards are necessary.

At LEI, when one of the boxes of coffee is empty at the point of use, there’s no card to pull coffee from the cabinet. You just do that, as the empty container is the signal.

But when the under counter coffee supply is gone, we take the card to our office administrator’s desk and she orders weekly to restock the office supply.

[…] This post was mentioned on Twitter by Mark Graban, Greg Lloyd. Greg Lloyd said: RT @LeanBlog: Quick Q&A about the LEI #kanban system in comments: How a Simple Office Kanban System Works – #Lean Blog – http://lnbg.us/1lN […]

[…] How a Simple Office Kanban System WorksKanban and Scrum – making the most of both […]

[…] of a kanban card from the Lean Enterprise Institute office (used to replenish coffee pods), that I featured in this blog post from 2010. See how LEI helps the Lean community? […]

[…] How a Simple Office Kanban System Works at the Lean Enterprise Institute (4,163) […]

[…] Example of simple kanban card at offices of Lean Enterprise Institute […]

Thank you for the article Mr. Graban. I really liked how you added pictures to not only tell the reader, but show how you use kanban in your everyday life. I also really liked how you brought using kanban and the two bin system into your own life, it is definitely something I am gonna bring into my home to help out my family!

[…] Example of simple kanban card at offices of Lean Enterprise Institute […]

Comments are closed.